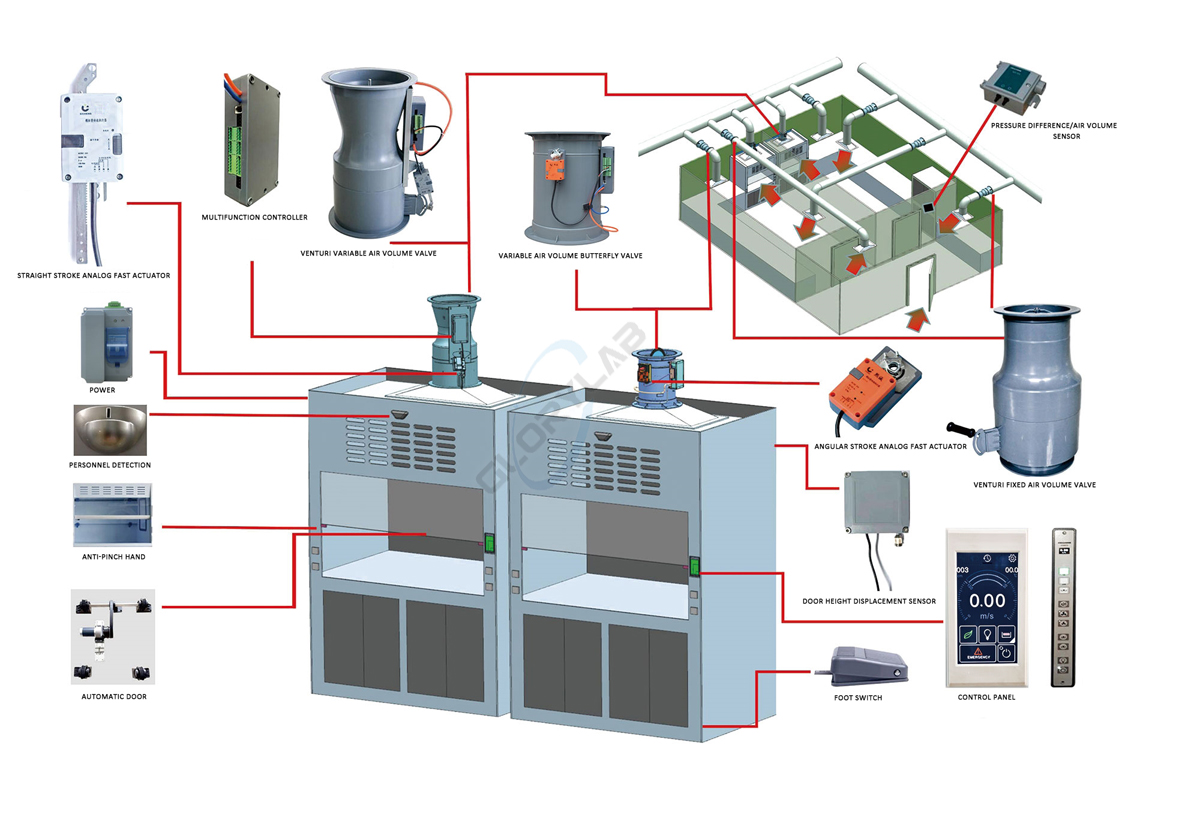

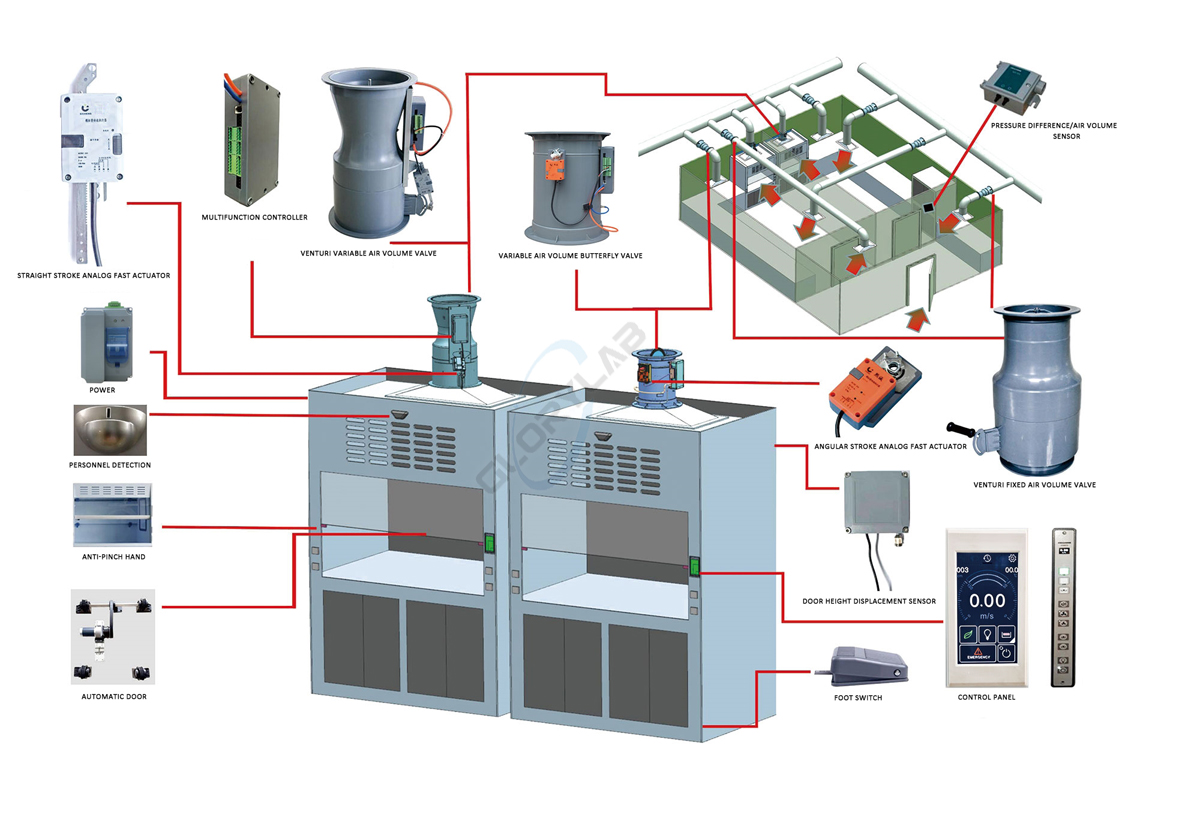

High Efficient Costly Variable Air Volume VAV Damper Fume Hood Valve

Model: JH-SA029

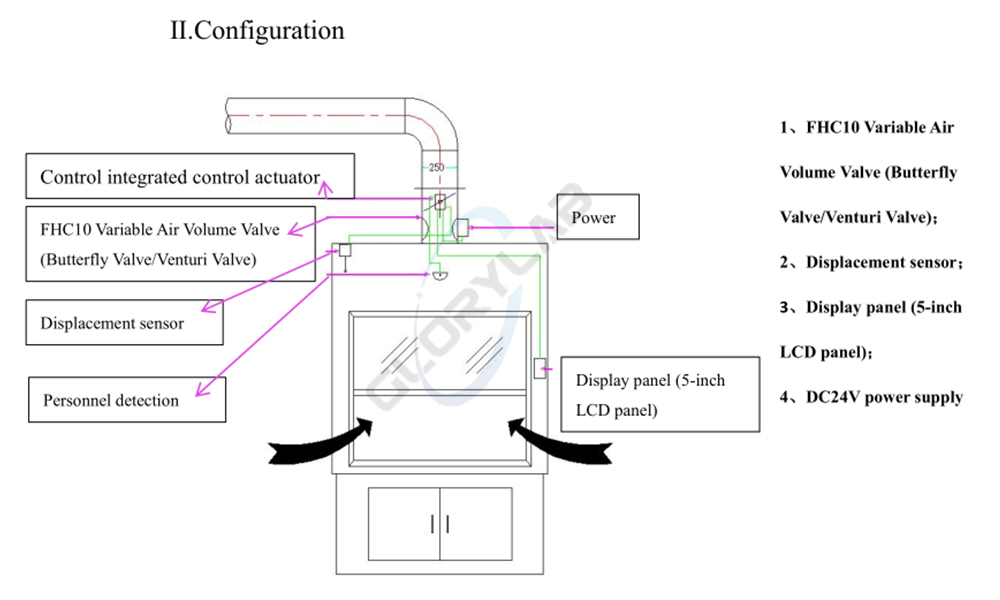

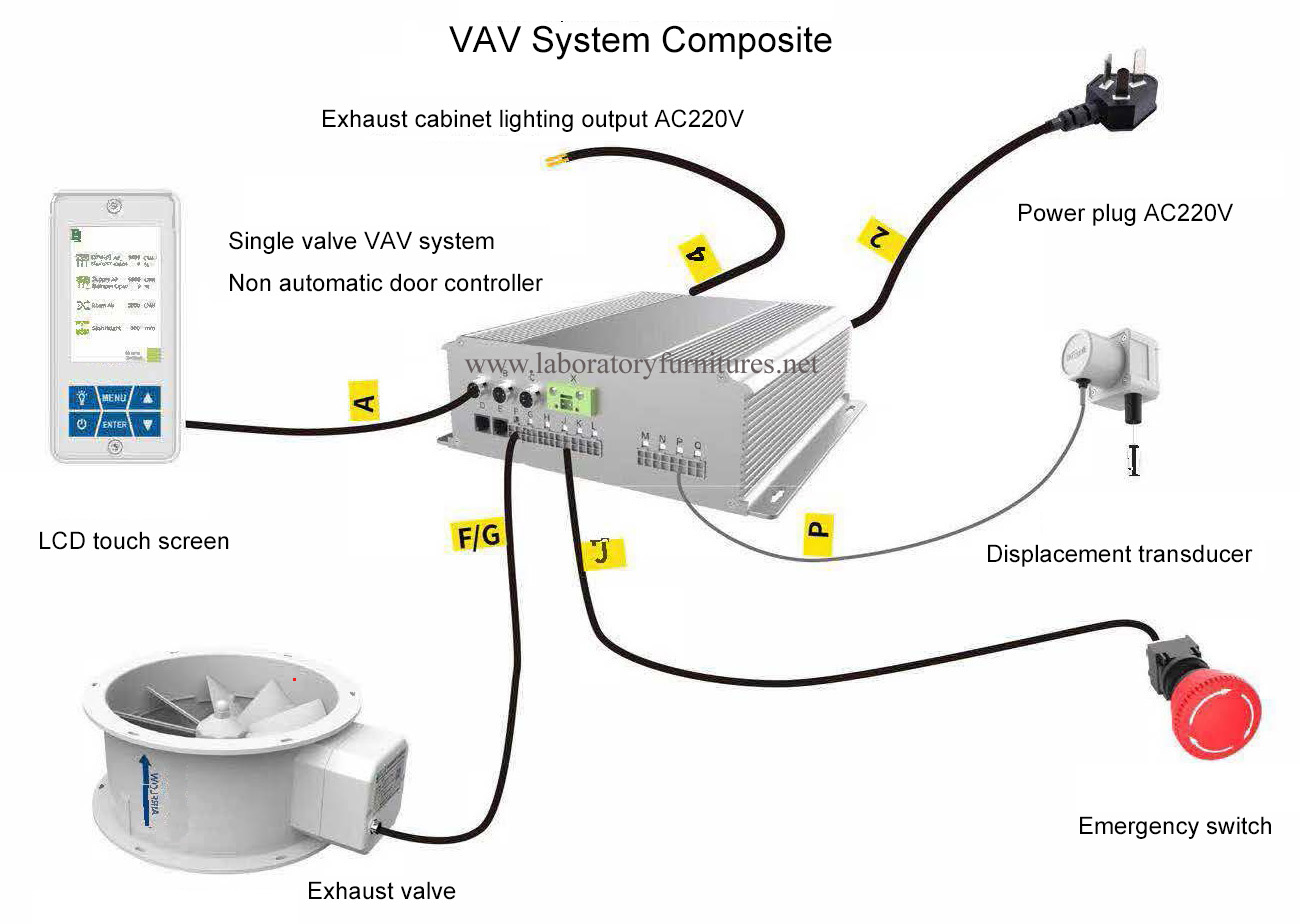

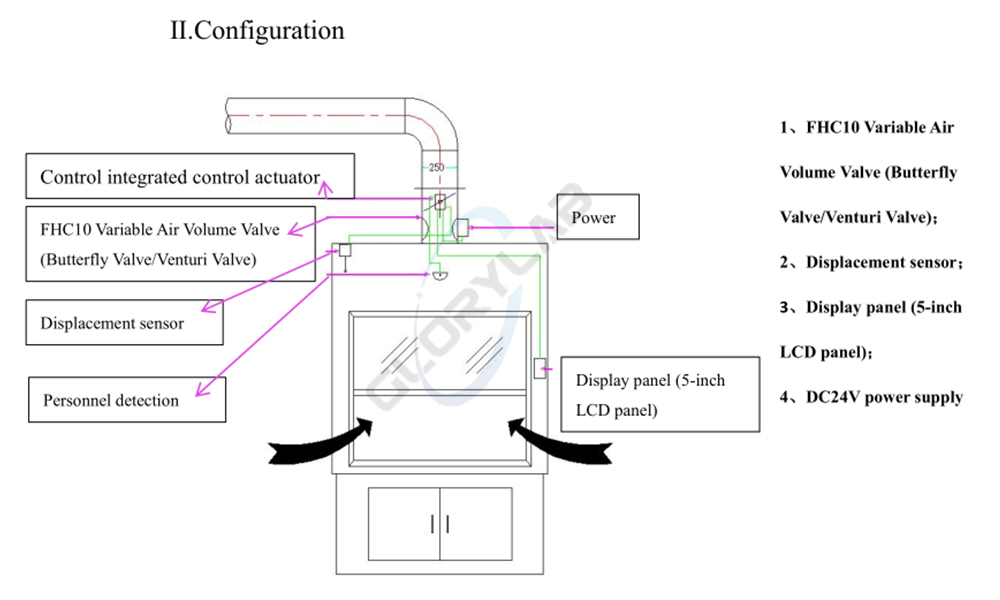

The fume cupboard variable air volume control system uses a controller that combines a fast actuator and a controller.

It monitors the opening of the fume cupboard window by means of a displacement sensor and quickly adjusts the opening of the damper to achieve a constant air velocity on the control surface. It is suitable for fume hood systems using butterfly or venturi valves.

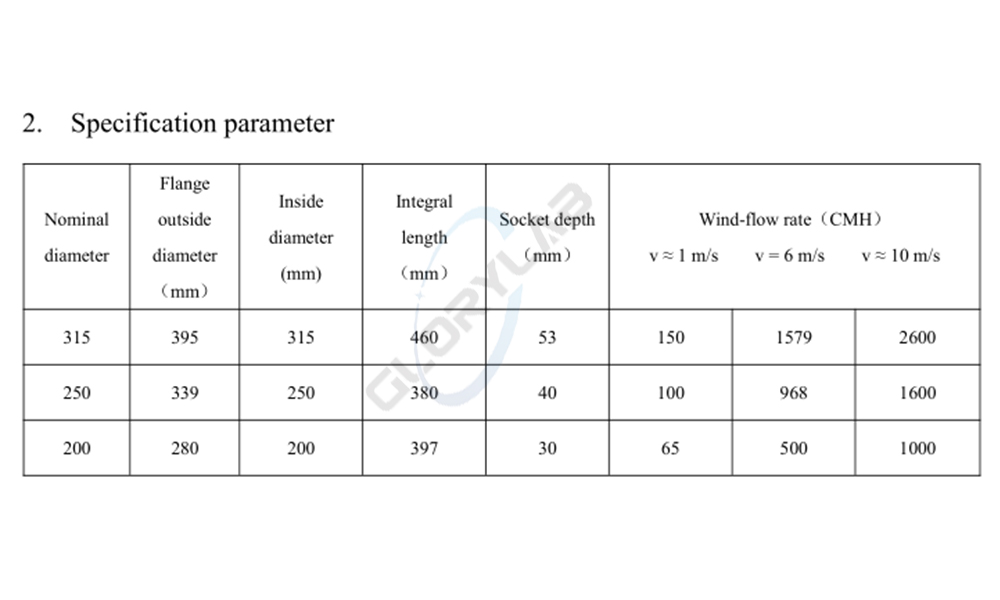

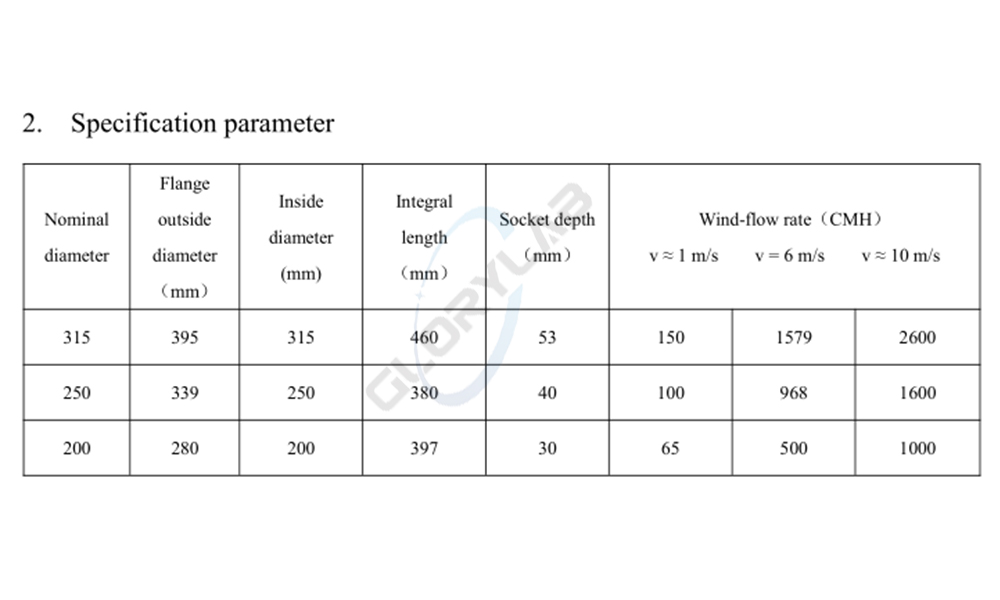

1. Variable air volume valve:

Controller and actuator integrated design, simple structure; 2S fast actuator, venturi using 3S linear

Stroke actuator, fast response speed (response within 1S, stable 2~3S); using the shape of the venturi nozzle

Measuring wind structure, accurate and stable wind volume, the error is less than ± negative 4% wind volume adjustment ratio of 16:1 (with third-party test report);

2.Controller

Controller and actuator integrated design, simple structure, easy to install.

Lighting control, status output, 485 communication (BMS communication port), support Modbus RTU communication protocol) and other functions.

3.Displacement Sensor

Measuring range: 1000MM—-5KΩMeasuring accuracy: ±0.1%, Connection: two-wire system, 0.6 stainless steel plastic-coated steel wire rope.

4.Control panel

(1) 5-inch screen is IPS LCD screen, resolution ratio:1280 x 720,colorful, clear and intuitive display;

(2) Touch screen based on Incell technology, more accurate and sensitive touch control;

(3) Can display surface wind speed, air volume change, window opening, exhaust air temperature and other information;

(4) With surface wind speed alarm, window open too large prompt, exhaust air temperature too high prompt function, with built-in timer function;

(5) Can control the start and stop of equipment, lighting, automatic door switch, automatic door prohibition;

(6) With emergency exhaust mode and energy-saving mode setting function.

Fume Hood Ventilation System